You probably have seen the video on YouTube about a molten Fonera, apparently due to overheating, which shows the plastic case completely deformed. Gizmodo (also in spanish) and other sites are also reporting on this. As usual, Fon has censored the post on their forums that broke the story, but alas, thanks to their partners at Google, here is a cached version. Even Martin Varsavsky seems worried about this. It seems the damage is obviously from heat, but could it have come from the Fonera itself?

I, and others, have our doubts about wether this video is a fake stunt, or a true story. It is true that the Fonera overheats, much more than would be expected from a consumer-electronics product, but to the point of causing physical damage to the plastic case?

The heat problem

Heat in electronics mostly comes from dropping voltage by converting current into it, in our case, the voltage regulator in the Fonera drops 5V to 3.3V at 500mA, resulting in the dissipation of 850mW. That’s right, we are dumping 850mW right into the atmosphere in the form of heat. This brings the operating conditions very close to the maximum ratings for this regulator, which has a maximum rated thermal resistance of 90ºC/W, my calculations put the operating conditions at 88ºC/W. Additionally, the wireless section of the Fonera is also converting a lot of energy into heat.

The measurements

After I finished my tests, I got a comment from Pobletewireless, regarding his own measurements of the heat problem, which are shown in very cool thermographs (no pun intended!) – much nicer than my rather rudimentary method.

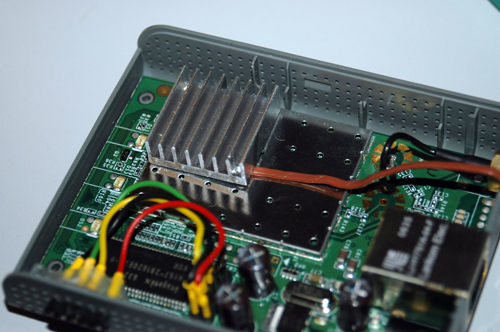

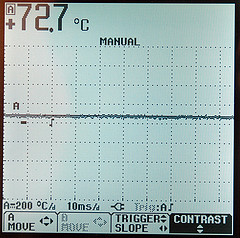

I measured the temperature of the Fonera using a thermocouple connected to a Fluke 123 Scopemeter via an 80TK thermocouple module. The thermocouple was placed in between the heatsink and RF shield, the case closed, and the Fonera powered, as can be seen in this picture:

After 10 minutes operating normally, the temperature had risen to an average of 72ºC, with a peak of 80ºC.

The second batch of measurements were performed drilling four small holes to allow the thermocouple into the casing, the locations are shown in the following picture:

Maximum temperature at one corner was 43ºC. Next, an attempt was made to melt the white lid of the Fonera, by exposing it to a high temperature airflow from a paint-stripping gun, and at the same time, applying slight pressure from below. The thermocouple was used to measure at which point the plastic became maleable, and deformation started. At around 100ºC, the plastic was soft enough that a solid object could change its shape – this is in line with ABS plastic thermal properties, which state a deflection temperature around 100ºC, depending on specific material composition.

As the deflection point test resulted as expected, the lid was then exposed to an airflow at 280ºC for two minutes. The result of this exposure is shown in the pictures below:

It’s obvious that some deformation has taken place, with discoloration and charring on the point where heat was directly applied. However, the front side of the lid had mostly retained its shape.

Conclusions

The Fonera does indeed run very hot, much hotter than it should, if anything, for the good of the internal parts. Electronic components are sensitive to heat, with maximum ratings given by each manufacturer in terms of storage and operating conditions. The higher the temperature, the lower the service life of any given component. Some are affected more than others, most notably, electrolytic capacitors have a high sensitivity to heat, as it can evaporate the electrolyte quicker, causing it to fail. The capacitors in the Fonera are made by Taicon, a taiwanese manufacturer, and are max-rated for 105ºC. From the datasheet [PDF], at this temperature, the capacitor will fail after some 2000 hours, around 83 days. Following Arrhenius’ Law, and since the area around the capacitors was found to be at around 52ºC, their expected life would be 7800 hours, or about 325 days – what a coincidence, almost a full year, after which your warranty has expired. Comparing the Fonera to a Meraki Mini, one realises that there is a serious design flaw, as apart from the Mini having a switched-mode regulator, the wireless section shares exactly the same design as the Fonera. The temperature measured outside the casing of the wireless section indicates that the junction temperature of the components inside has to be ridiculously high. So, one conclusion is that the Foneras will eventually fail due to overheating, and it will probably happen sooner than later.

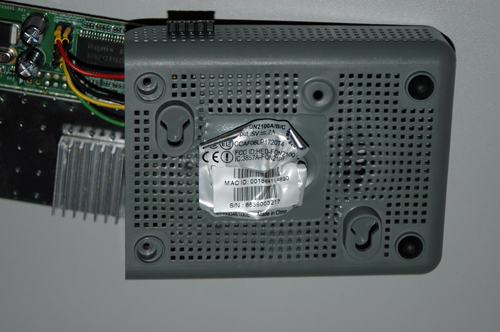

On the deformation / melting video – in my opinion, it’s not real. At least, it couldn’t have happened without the Fonera reaching temperatures around the whole casing that would have caused some components to blow up (for example, the capacitors). The Fonera could not have undergone such an extreme temperature, and still function as shown on the video. The temperature gradient between the heatsink and one corner of the case is almost 2:1, thus, to reach a deformation temperature of say 200ºC at the corner, the heatsink must have been running at 400ºC! A final bit of evidence – the sticker. If you look closely at the video, the sticker on the bottom of the Fonera looks almost unscathed. Here is a picture of what it looks like after applying a 250ºC airflow for 30 seconds, which causes the plastic to deform:

Obviously, a more prolongued exposure would have damaged it even more. In all honesty, I would love to get more details from the guy who made the video, as it stands right now, I’d call it a hoax.